Hinge & Hardware Insertion Machines

Bore and hinge or hardware insertion machines with magazine feed for the automatic processing of hinges, hinge mounting plates and RTA fittings. Robustness, durability and ease of use distinguish Gannomat's automatic drilling and insertion machines.

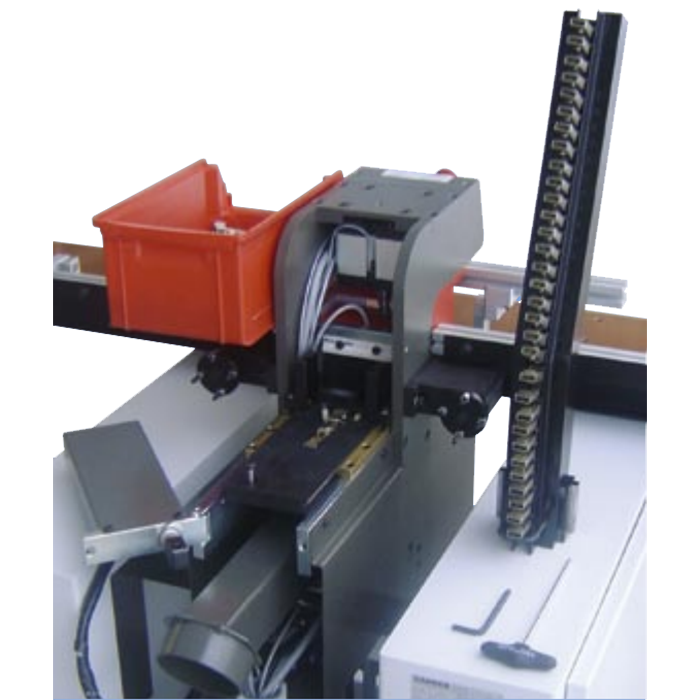

Express S1

Express S1 provides a single head for boring and insertion of hinges, hinge plates, drawer brackets and RTA fittings.

- Rigid steel frame construction.

- Integrated drilling and inserting unit.

- Standard 4-spindle drill head with high-speed spindle chucks.

- Automatic feeding and inserting of hinges or RTA’s by magazine and inserting die.

- Cycle time approximately 5 seconds for drilling AND inserting.

- Lighted program selector buttons for drilling only, or drilling and inserting modes.

- Drilling from below providing accuracy, speed, protection of product, and safety.

- Quick-change magazine and inserting die for change between hinge models or change between hinge insertion and RTA insertion.

Express S2

Express S2 motorized movement of the stations, programmable through touch screen. Programs can also be loaded by barcode reader.

Express S2 provides the quickest and most accurate way on the market to insert hinges, hinge plates, hinges with plates attached and drawer brackets.

- Rigid steel frame construction.

- Integrated drilling and inserting unit.

- Automatic feeding and inserting of hinges by magazine and inserting die.

- Standard 4-spindle drill head with high-speed spindle chucks.

- Right drill head(s) travel on linear rails and are locked with a pneumatic brake controlled by push button for fast alignment to different length doors. Cycle time approximately 5 seconds for drilling AND inserting 2 hinges.

- Program selector switch for drilling only, or drilling and inserting modes.

- Drilling from below providing accuracy, speed, protection of product, and safety.

- Available with 1, 2, 3 or more drilling and inserting stations (i.e. S1, S2, S3, etc.)

- The well thought out design of a tilt forward magazine facilitates the easy loading of hardware during the 5 second machine cycle.

- Fully automatic maintenance-free electronic control operated by foot pedal.

- Dual tilt-stop rails at each head allow for more hinge setbacks.

Express S2/RTA

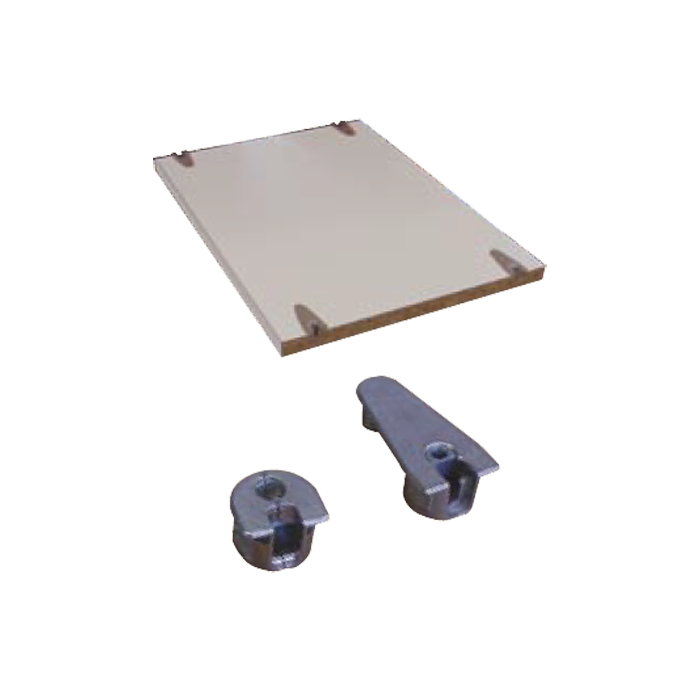

The Express RTA machine inserts double and single post RTA fittings, plastic and metal. Also has the ability to insert flush single post RTA’s.

- Drills and inserts two RTA fittings with a total cycle time of 5 seconds.

- Aligns cam fittings flush and perpendicular to the edge of the workpiece.

- Drilling from below providing accuracy, speed, protection of product, and safety.

- The re-drill safety will not allow the machine to cycle if an already inserted fitting is detected.

- Only viable way to insert flush fittings consistently.

- Magazine holds approximately 35 fittings each

- Operating cycle of 4.5 seconds

Dimensions:

55" w x 48" d x 55" h

Specifications:

- Magazine - holds approximately 35 fittings each

- Working width - 180mm to 800mm

- Operating cycle - 4.5 seconds

- Dust extraction tube 100mm. Dust collection required.

Express S1 CNC

CNC bore and hinge insertion machine with magazine feeding for the automatic processing of hinges and hinge mounting plates. Robust, durable and easy-to-use. These features distinguish our automatic CNC controlled drilling and insertion machines from any other machine on the market.

- CNC controlled hinge boring and inserter for high capacity

- Flexibility through the CNC control

- Massive and robust drilling units

- Inserting die made of steel for a long lifetime of use

- Solid wood drilling with standard 1,5 kW motor

- Safety-control with metal-detector (option)

Express S2 CNC

Express S2M

Express S2 Motorized movement of the stations, programmable through touch screen. Programs can also be loaded by barcode reader.